Adsorbent Bed-type Mercury and H2S Removal Units

Applications

Removal of mercury and H2S from natural gas by adsorption process

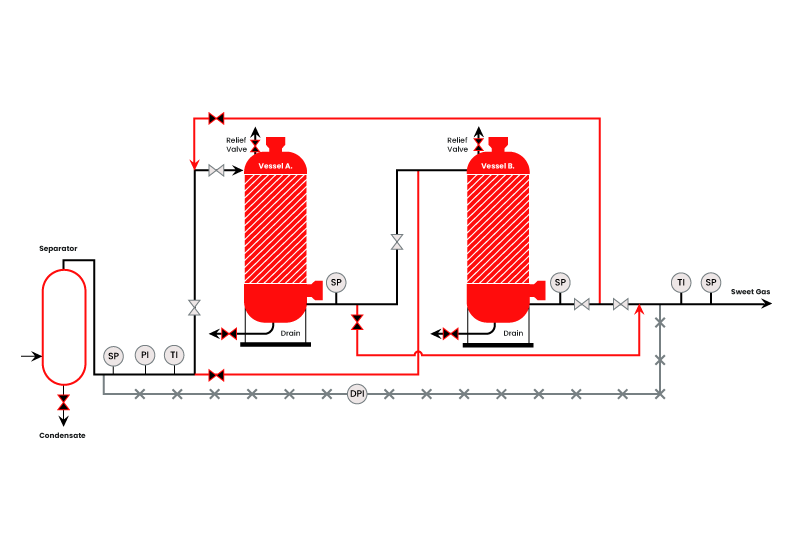

Basic Process Description

The feed gas is introduced to the top of the adsorber tower. In its downflow, feed gas contacts the adsorbent bed which selectivity adsorbs Mercury and H2S. A lead/lag design provides for maximum flexibility in vessel configuration and the most efficient use of the media. In this mode gas flows through the lead bed and then through the second bed, known as the lag or guard bed. When the lead bed becomes spent, it is taken off-line for short time to replace adsorbent media. During this short time the bed which lagged, treats the full gas flow. When the new media is installed, the vessels are switched. The lag bed becomes the lead bed, and the lead bed is lined-up into the lag position. In this way operators can maximise the capacity of the beds to remove the impurities ensuring optimum use and operating life of the adsorbent.

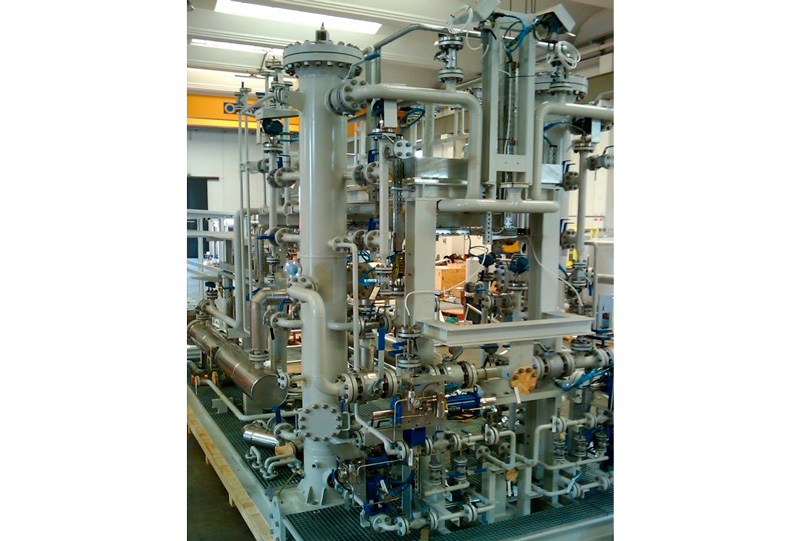

The unit is completed with interconnecting piping, valves, steelworks, instrumentation and control systems.

Depending upon the extension of the scope of supply, the unit may be provided with additional inlet separator.