Fuel Gas Treatment, Compression & Metering Units

Applications

Fuel gas conditioning for gas turbine

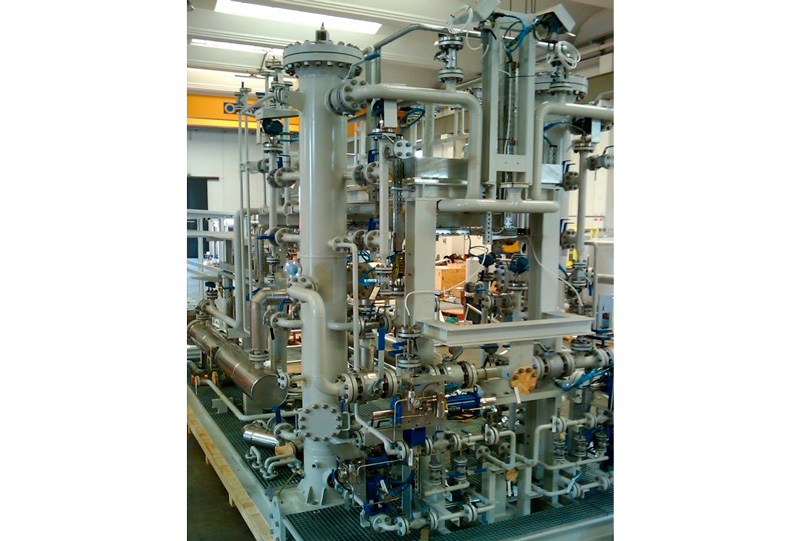

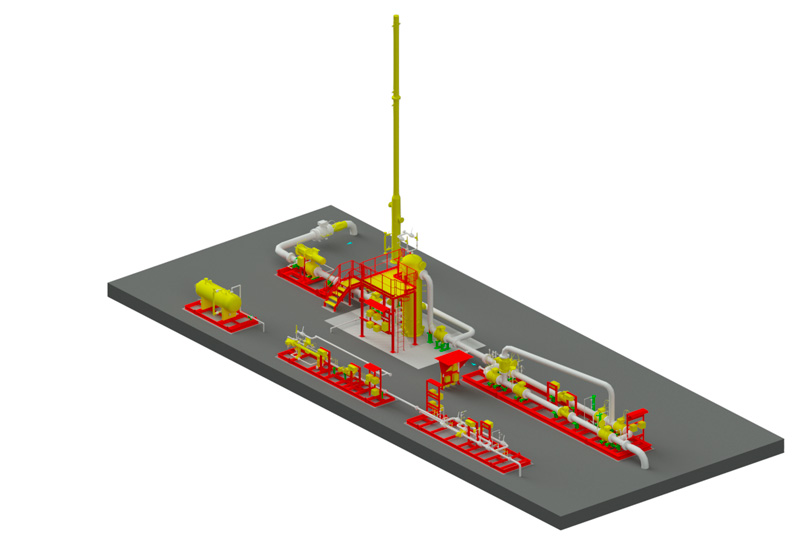

Basic Process Description

The fuel gas system is designed to achieve the pressure, temperature, flow and cleanliness as required by the specification of the gas turbines.

The system is generally composed by the following main sections:

- Inlet emergency shutdown valve (ESDV);

- Filtering and separation section for removal of liquid droplets and solid particles: typical configuration is with multi-cyclones separator followed by two-stage filter-separator with coalescing cartdriges and vane pack mist eliminator;

- Dew point heater (indirect water bath or electric type) to provide the required superheat temperature above the gas dew point;

- Where applicable, a pressure boosting station, through one or more compression train;

- Pressure regulation station, usually composed by 2×100% parallel lines, each one composed by the slam shut-off valve, monitoring and regulating valves;

- Dew point and gas chromatograph analyzers;

- Metering station, including flow meter and flow computer;

- Last chance filters with particles removal cartridges.

The unit is completed with interconnecting piping, valves, steelworks, instrumentation and control systems.

Depending upon the extension of the scope of supply, the fuel gas system may be provided with condensate collection system and cold vent stack.