Solid Bed Desiccant-type Gas Dehydration Units

Applications

Removal of water from natural gas by absorption process

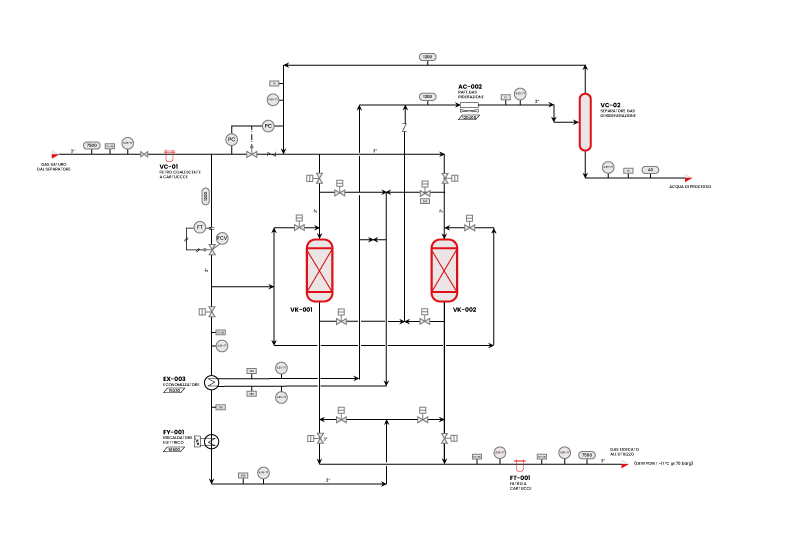

Basic Process Description

The feed gas is introduced to the top of the adsorber tower where it contacts downward the molecular sieves or silica/alumina gels solid desiccant bed which selectivity retains the water. The unit consists of two or more towers and associated regeneration circuit. One tower is onstream adsorbing the water from the treated gas while the other tower is being regenerated and cooled. Hot gas is used to drive off the adsorbed water from the desiccant, after which desiccant bed is cooled with an unheated gas stream. Towers are switched before the on-stream tower becomes water saturated. One bed operates in adsorption while the second operates in desorption/regeneration, and both beds are switched periodically at specified times in the cycle though on-off actuated valves. In the regeneration step, a slipstream of the dried gas is used as regeneration gas to drive off the adsorbed water from the desiccant, after being heated to the appropriate regeneration temperature. The hot regeneration gas, complete with desorbed water, gets cooled in the regeneration gas cooler and then passes through the regeneration gas separator to knock out the condensate and separate the desorbed water. Thereon the gas is recycled back to the inlet of the unit through Regeneration gas compressor.

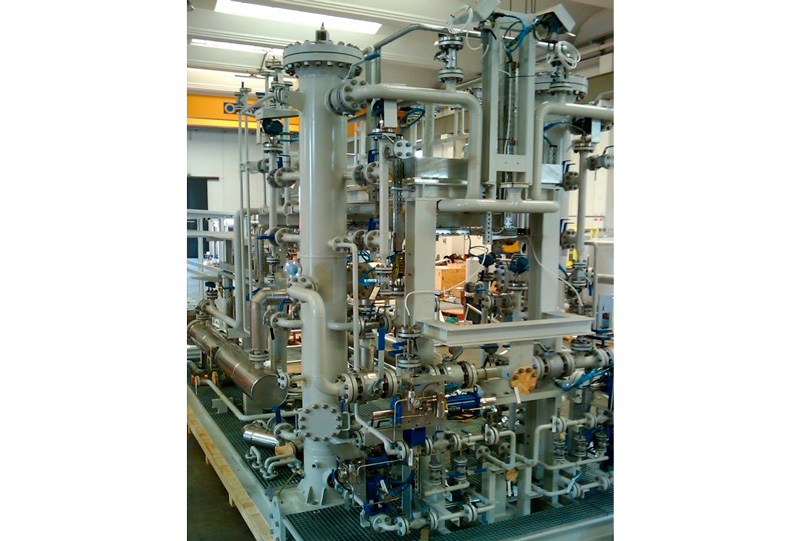

The unit is completed with interconnecting piping, valves, steelworks, instrumentation and control systems.

Depending upon the extension of the scope of supply, the treated gas section may be provided with additional inlet separator and outlet particles filter.