Solid Bed Desiccant-type Heatless Air Dryers

Applications

Removal of water from air by absorption process

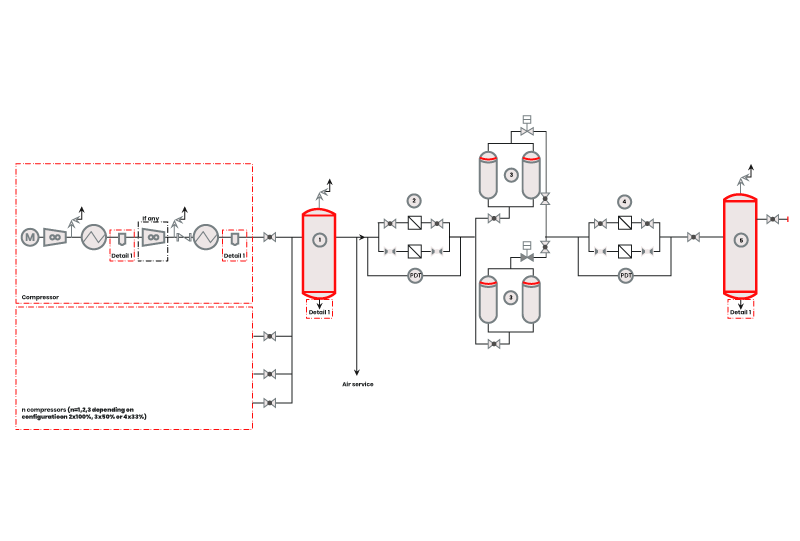

Basic Process Description

The wet air is treated first by 2×100% pre-filters to remove liquid droplets and solids. Pre-filters contain high efficiency coalescing elements. Filtered wet air is treated by heatless pressure swing dryer with two adsorption towers that operate alternatively in drying and regeneration mode. The wet air flows up through the adsorbent bed which removes water to below the required specifications. The adsorbent bed consists of activated alumina, top and bottom of the bed is packed with inert spheres. Regeneration of the bed is carried out by depressurisation through a flow orifice and counter-current purge of dry product air. Regeneration air is regulated by a valve and it is then vented to atmosphere through a silencer to limit discharge noise. Re-pressurisation at the end of regeneration phase is obtained by opening a parallel equalising valve. The dry air is treated in 2×100% after-filters to remove any desiccant fines.

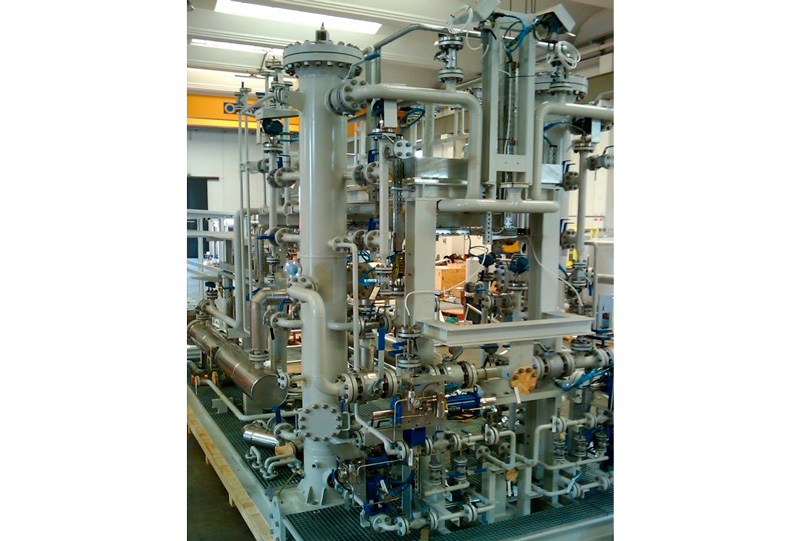

The unit is completed with interconnecting piping, valves, steelworks, instrumentation and control systems.